In the modern mining industry, one will find that most of the industry’s reputable operators have implemented a safety strategy.

The slogan “one life lost is one life to many” is regularly used as the key message in most occupational safety drives – all with varying success.

A clear success story is Mopani Copper Mines, who implemented its SAFEMINING plan in 2014.

This article first appeared in Mining Review Africa Issue 2, 2019

This vigorously driven strategy has not only proven successful at Mopani’s many mines, but it is proving to be a beacon of excellence within the mining industry.

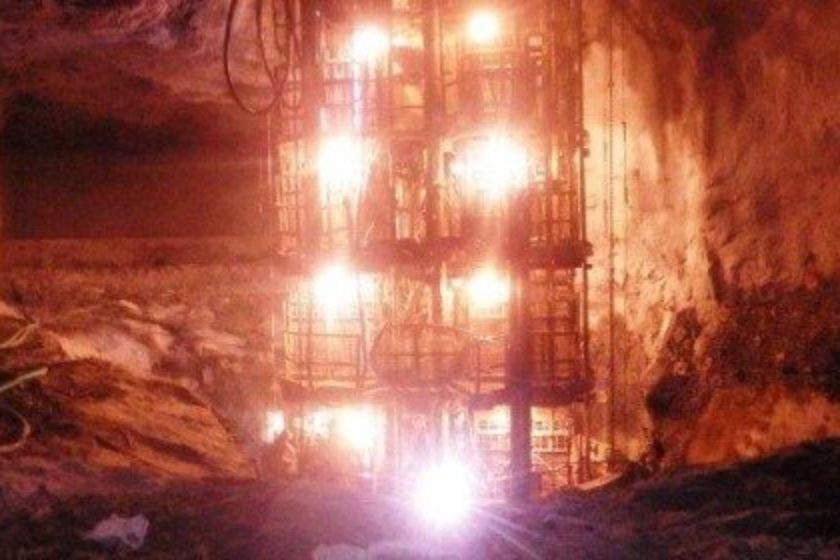

At Mopani Copper Mine’s Kitwe operations in Zambia, there is a clear success story in Group R Mining & Exploration Zambia – an operating subsidiary of Pan African mechanised and trackless mining contractor Group R Holdings of Mauritius.

Not only did Group R embrace the SAFEMINING drive of Mopani Copper Mines, but has made it part of their daily conduct and business DNA.

The success of this is evident in that Group R has not had a single work fatality since its inception in 2010.

Moreover, the company has achieved an enviable track record of working five years without a single lost-time injury (LTI), a milestone that was achieved in late December 2018 at Mopani’s SOB Shaft.

“We at Mopani are extremely proud of the achievements of Group R and their unwavering dedication to mine safety. We would like to see this dedication and passion from all our contractors in all our operations” says Mopani Copper Mines CEO Chris Vermeulen.

The management team at Group R is firm in its approach to mine safety. Daily safety meetings are not seen as a tedious task but forms an integral part of its planning, policy-making and operational systems.

It is Group R’s belief that safety must be front of mind in everything that you do.

“Our client, Mopani Copper Mines, introduced and demanded that we work according to their international best standards for safety. As a contractor we had the choice to merely tick the boxes and show compliance or to embrace the spirit of the standards. We chose to embrace their safety protocol as part of our operations” says Group R Holdings COO Hein van Staden.

Group R believes that its five year LTI-free safety achievement at Mopani Copper Mines is merely just a measure of past performance and that providing a safe working space is not based on the past, but rather based on the continual safety performance of each and every future shift. Every shift demands 110% dedication.

“At Group R we believe that the management team is the greatest driver of operational safety, while our workers are the true custodians of safe practice. This is evident in their dedicated to daily safety at work,” say Van Staden.

Group R believes it its duty as African operator to be responsible for continuously investing in the incubation of a better, more inclusive and safer working environment within the African mining sector. This dedication is clearly visible through the safety accolades that it has achieved.

As a proud Zambian company, Group R Mining & Exploration Zambia would like to showcase to the world that Zambia has world-class mining contractors helping to benchmark Zambia’s mining sector on the African continent.

Source: Mining Review Africa